Green, low-carbon and high-quality developments top of the agenda at Chinese steel conference

Date:2023/12/22 Source: CISDI

CISDI recently hosted China’s 14th Steel Conference in Chongqing.

The event was sponsored by the Chinese Society for Metals and co-organised by the Chongqing Society for Metals.

Over 2,000 from the steel sector attended, including specialists in science, technology and engineering and providers of tech and equipment.

They shared their achievements in mining, metallurgy and materials theory and process, production, intelligent and low-carbon applications.

Hot topics in global steel were discussed at a number of seminars and exhibitors came from across China and abroad.

At the general meeting, the latest developments in ferrous metallurgy and applications for green, low-carbon and digital advancements were delivered.

Speakers included Yong Gan, honorary president of the Chinese Society for Metals and a member of Chinese Academy of Engineering; Edwin Basson, director general of the World Steel Association; Angui Hou, CEO of China Baowu Group; Kazuhisa Fukuda, executive vice president of Nippon Steel; Xinping Mao, Dean of the Institute of Carbon Neutrality at the University of Science and Technology Beijing, and Kim Ki Soo, vice president of POSCO.

In his welcoming speech, Xuewen Xiao, chairman of CISDI Group, told the audience: “CISDI’s bridging role between applied science and steel industries is down to its 65-year pursuit of technological innovation.”

“Our engineering designs improve steel industrial competitiveness and our core equipment manufacturing is a pivotal support for a higher standard of steel development.”

He urged all organisations to speed up their digitalisation and prioritise the transition to green and low-carbon production.

Lectures by ten of CISDI’s experts proved a highlight of the conference. They gave a detailed analysis of low-carbon, non-blast furnace ironmaking, electrometallurgy and scraps, automation and smart manufacturing.

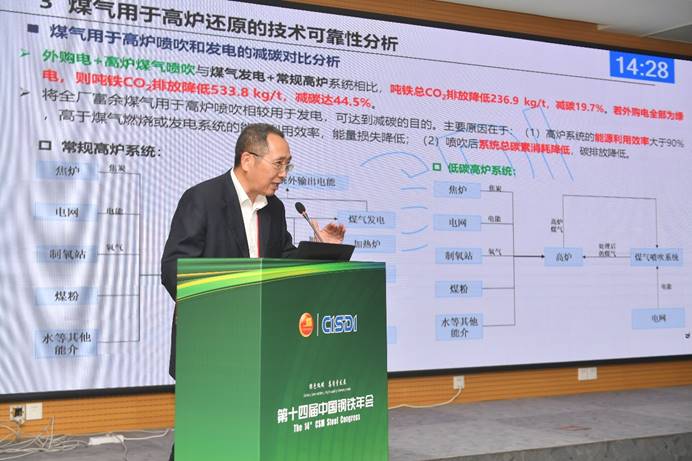

Their sessions included details of the latest methods to reduce carbon emissions in blast furnace and basic oxygen furnace processes, thermal analysis models for oxygen-enriched and low-carbon smelting.

CISDI’s developments, such as ultra-high-power IGBT DC power-based and smart electric arc furnace tech, also featured in their reports and Binxin Steel’s full-process smart factory in China’s Jiangsu Province was sited as a leading example of tech taking steel production to greener environmental standards.

The 14th CSM Steel Conference was held in Chongqing, China

Yong Gan delivers a report on advancing China’s steel industry to higher standards

Edwin Basson delivered a lecture on the development of a global low-carbon steel industry via video link

CISDI chairman Xuewen Xiao opened the conference

Visitors at CISDI’s exhibition booth

CISDI’s ironmaking expert Zhongping Zou gave a talk on methods to reduce carbon emissions in blast furnace – basic oxygen furnace process

A special report on CISDI’s UHP IGBT DC power-based and smart EAF tech was delivered by Yuchuan Zhang, the company’s steelmaking expert

Link:

CISDI chair Xuewen Xiao told the 14th CSM Steel Conference how CISDI’s innovative results are advancing greener, low-carbon Chinese steel.

“Our innovations will blaze a trail for China’s steel industry to first reduce carbon emissions, reach a carbon peak and finally hit carbon neutral,” he explained. “A widespread effort across all sectors will be needed to make this innovation-driven transformation.”

Over a decade of CISDI’s strategic planning, commercialisation and research and development has achieved multiple breakthroughs in low-carbon blast furnace and hydrogen-based shaft furnace ironmaking and green electric arc furnace steelmaking.

A third generation CISDI AutoARC EAF is about to be exported to a steel plant in Hungary, marking a significant new opening in the European market.

Progress has been made in CISDI’s integrated BF-BOF process. The world’s first low-carbon blast furnace in a volume of 2,000 cubic metres went operational this year at a Chinese steel plant. It is performing so outstandingly, it has been deemed worthy of further research and application.

The green furnace has reduced the coke ratio from five to eight kg and the fuel ratio has decreased from 20 to 30 kilograms per tonne of hot metal. A continuous, stable 10 per cent reduction in carbon emissions has been achieved and cost savings amount to USD 1.37 to 4.11 per tonne of hot metal production.

The research and development of a new shaft furnace and cost-effective low-carbon routes are also steaming ahead. Their industrial implementation has been put on CISDI’s agenda of providing carbon-reduction product and service.

CISDI also took the lead in building a public service platform for the National Development and Reform Commission in support of steel sector achievements in carbon peak and neutrality.

The platform enables a ‘one-stop’ full life-cycle low-carbon tech and service - from consulting, research and development and design to technological verification, appraisal and application.

Contract-signing for the export of CISDI’s generation-3 green EAF to Europe. LtoR: Xuewen Xiao of CISDI Group, Sanjeev Gupta of LIBERTY Steel Group and Márton Nagy, Hungary’s Minister of Economic Development

A global first - CISDI’s low-carbon blast furnace (2,000m3) demo project in China