CISDI - committed to technology and innovation for greener, higher quality steel production

Date:2022/3/17 Source: CISDI

CISDI is a technology-based company

and innovation is at the top of our agenda. This

commitment was emphasised at the company’s annual meeting earlier this year,

with chairman Xuewen Xiao’s pledge: “We will intensify our research. Only by

improving the role of innovation in our market planning and enhancing its value

creation can we pursue technological developments.” Underpinned

by our tech-first strategy, in 2021 our achievements in innovation were many.

Over 600 patents were applied for, nine overseas patents were awarded, six

standards were released and nine technological rewards and honours were granted

by provincial and national Chinese institutes. We have

formed close working relationships and continued our coordinated research

programmes with multiple top universities and institutions in China and around

the world. In the

quest for a greener, low-carbon steel sector, we built a Low-Carbon Technology

Research Institute which will focus on breakthrough research into low carbon

technologies. Our

hydrogen metallurgy, carbon circulation, intelligent-control phase coupling and

other critical tech are now ready to market and wider applications are being

sought. In 2021 we

achieved multiple technology firsts and breakthroughs for the steel production

process: ² CISDI-AutoARCTM

was hot commissioned at Pangang Changcheng Special Steel in China’s Sichuan

Province ² A stove fume

desulphurisation system was applied at Tangshan Songting Steel in China’s Hebei

Province ² Ultra-low emission

total solutions achieved outstanding emission and low-carbon metallurgy results

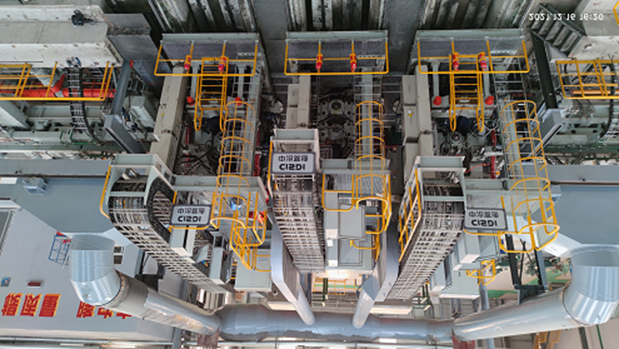

at a steel plant in Rizhao City in China’s Shandong Province ² The CISDI-developed

universal mill and 3-roll cross tube mill met their production targets at

Chinese rolling lines ² Intelligent platforms

and products transformed Baowu Maanshan Steel, Yongfeng Steel and Pangang

Xichang Steel to smarter production, resulting in greater efficiency and higher

quality products. Digital

transformation has sped up across CISDI. Measurement, modelling, engineering

and project management businesses were digitalised, enhancing our engineering

efficiency and accuracy. A standardised digital design workflow has been

formulated to respond to steel plant rebuild and post-pandemic construction

challenges. In 2022,

we are helping clients and partners around the globe to build intelligent,

green, low-carbon and super efficient steel plants. This requires us to

redouble efforts to create ever-greater innovations in front-edge technology

and develop more core expertise. We will

focus on breakthroughs in low-carbon technological research and project

application. Our intelligent achievements at Yongfeng and Shaogang plants will

enable us to further optimise and apply our intelligent platform-based

solutions. “Based on

the strategies and objectives set at our annual meeting, we are already on the

right track to continue developing advanced total solutions for global clients

and playing our part in transforming global steel to greener, higher-quality

levels,” concluded Mr Xiao. CISDI’s

annual meeting 2022 was held at the company’s Chongqing HQ The

CISDI-developed universal mill is operating smoothly at Yongyang Special Steel Our fume

deNOx and deSOx expertise has gained ultra-low emission results at a Chinese

steel plant China’s

first full-process Greenfield smart plant based on a unified industrial

internet platform has been built by CISDI at Yongfeng Steel