First blast furnace ramps up at Zenith Nantong

Date:2022/6/6 Source: CISDI

——

Revolutionary green and intelligent blast furnace is up and running

Zenith Nantong Steel’s revolutionary CISDI-built blast furnace 3 has been blown in and is tapping hot metal as scheduled.

It is the first of its kind at the new modern steel plant in Jiangsu Province. It will now come on stream to meet ramp-up targets.

Zenith Nantong Steel’s blast furnace 3 is operational

✧ Future-oriented high-end Greenfield steel plant

The Nantong steel plant under Zenith Group is the largest of its kind in the world.

CISDI has been tasked with the plant’s master plan, general design, EPC management and more than ten of the main individual plant’s EPC-based services.

One of Zenith’s most significant builders and partners, CISDI is focussed on designs which increase efficiency, green and intelligent production and on hitting world-class targets for equipment, environmental protection and management.

Nantong will rank as a global green and smart demo, showcasing:

• Zero liquid and solid waste discharges by complete internal recycling

• Waste gas 30 per cent below than China’s ultra-low emissions standard

• Clean tech and facilities applied to 90 per cent of the plant’s transportation

• Sectoral leading indicators achieved in energy consumption by all individual plants.

Nantong Steel’s construction is on-schedule. The plant will create a super brand for Zenith, which is forming strategic layout with a headquarters in Changzhou City and three bases in Jiangsu Province.

An aerial view of Zenith Nantong Steel. The plant will feature green, high-quality, super-efficient and intelligent levels

✧ Blast furnace 3 is a front-runner for high efficiency, green and smart operations

Blast furnace 3 was the first of the three to go into operation at Nantong Steel. Construction took around 18 months.

The project broke ground in September 2020. Its top structures were capped in March 2021 and its stoves were heated up seven months later.

March 2022 saw the first of three blast furnaces blown in. It was built by CISDI as a modern demo, boasting a long service life, super efficiency and green and intelligent operations.

Furnaces 1 and 2 are under construction, also with CISDI as EPC-based service provider.

Nantong’s blast furnace 3, operating at night

✧ State-of-the-art critical tech and equipment

A number of CISDI’s critical high-efficiency, low-consumption tech and equipment for large blast furnaces has been applied:

• three-section furnace proper structure

• thick-wall profile tech with cast-iron cooling staves

• top-combustion stoves with innovative ceramic burners, which result in low-nitrogen combustion

• three tapholes arranged at a flat casthouse platform with two main workshop buildings

• a high level of mechanisation and automation for the casthouse

• siphon and bottom-filtering tech applied for the slag granulation system

• single ladle transfer process/solution applied to hot metal transport, reducing hot metal and temperature losses.

✧ Green production

A host of CISDI’s world-class tech and facilities for achieving dust collection, reduced consumption and low emissions have been applied:

• furnace top’s equalising system with gas recovery

• gas dry cleaning system

• refined desulphurisation for top gas recovery turbine

• all flying dust areas to be fully enclosed

• a well-functioning dust collection system, applying intermediate dust hopper plus negative-pressure suction-exhaust car to create an enclosed dust transport system.

✧ Intelligent production

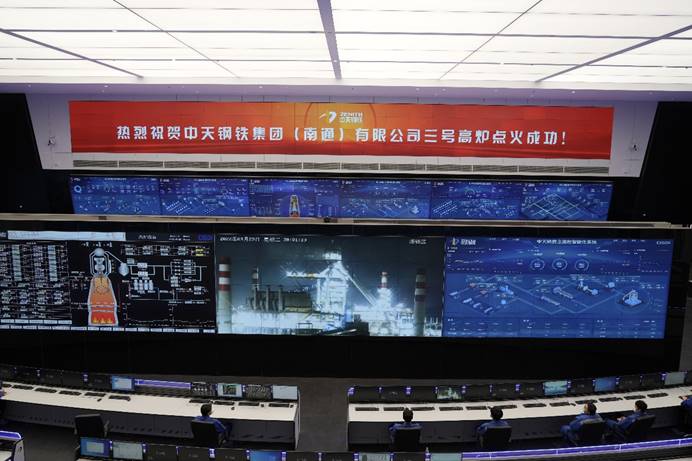

An upstream-ironmaking centralised control centre has been built for Nantong’s three blast furnaces.

CISDI’s massive scale, long-distance centralised control expertise and its intelligent system combining big data, online simulation and math model technologies have been brought into play.

The control centre plays a transformative role in taking conventional assisted decision-making to smart levels. It is capable of servicing the largest of production capacities and features the highest degree of duty/post integration in China’s steel sector.

The CISDI-built centralised control centre at Nantong Steel

✧ All challenges overcome

Once construction began, hundreds of CISDI engineers and managers worked closely with Zenith’s staff and partners to ensure all schedule and quality targets were met, despite challenges posed by typhoons and storms and the pandemic.

They showed tenaciousness and outstanding workmanship.

At blast furnace 3’s startup ceremony, Caiping Dong, the chairman of Zenith Group, expressed his appreciation and respect for the diligence and intelligence CISDI teams had displayed over 500-plus days and nights to successfully build a first-of-its-kind steel plant on the 7.6-square-kilometre site.

A CISDI engineer onsite, proposing solutions to Zenith and construction workers