S&T: CISDI’s best tech in limelight at China’s steel achievements exhibition

Date:2020/10/16 Source: CISDI

CISDI showcased its major tech achievements at a steel exhibition to mark the end of China’s 13th five-year plan.

CISDI has been committed to researching and developing innovations which enable industry to advance and improve.

Over 90 per cent of its R&D results are industry leaders in China and 20 per cent are world-class.

Hundreds of CISDI’s technical developments and products are not only improving the steel industry, but society too. CISDI is committed to its social responsibility and has been awarded six national prizes and 45 provincial/ministerial prizes for scientific and technological achievements.

The company has been granted 1,178 patents, including 316 inventions, during the past five years.

2020 marks the end of China’s 13th five-year plan and the start of the next five-year plan.

The major tech achievements CISDI showcased at the event are:

✧ Large blast furnace critical tech and application for high efficiency and long campaign

This systematic critical tech creates high-efficiency, low-consumption large blast furnaces and provides total solutions for the technological process, the profile design, structures, core equipment and intelligent production control.

It has transformed 16 of China’s large blast furnaces, accounting for 70 per cent of the market share.

Formosa Ha Tinh Steel’s two 4,350-cubic-metre blast furnaces in Vietnam feature the critical tech and are recording world-class indicators for productivity, coke and fuel ratios.

Another influential application is at TATA Steel’s Kalinganagar 5,870-cubic-metre blast furnace, which is under construction.

CISDI’s development also contributes to energy conservation, emission reduction, and large-scale installations, efficient and low-consumption developments for blast furnace ironmaking.

It was awarded second prize in awards for China’s technological advancements in 2016.

Baowu Zhanjiang Steel’s two 5,050-cubic-metre blast furnaces, benchmark applications of CISDI’s critical tech

✧ Green, efficient electric arc furnace

The full-scrap melting process consumes huge amounts of energy, produces unstable liquid steel and generates dioxin. CISDI’s green EAF makes the process more efficient, cleaner and conserves energy.

The green EAF features an ultra-high-power, smart power supply system, efficient, ultra-clean melting, green transport and enables preheating of the scrap and integrated control. It has recorded world-class indicators and was awarded a silver medal in awards for China’s technological advancements in 2019.

Over half of China’s EAF production now operates with CISDI’s green, efficient EAF tech and equipment. Overseas, the EAF is in operation at steel plants in Turkey, Vietnam and Indonesia.

A 90-tonne EAF in operation at VKS steel plant in Vietnam

✧ Systematic, integrated optimisation throughout steel manufacturing processes

Based on the energy, mass, iron, emission and time flows in steel manufacturing processes, CISDI has developed total consulting solutions for integrated optimisation of the overall processes, at the interfaces, for energy utilisation and environmental protection.

Its solutions were awarded a first prize in awards for China’s metallurgical technological achievements in 2016.

The solutions targeted to production expansion and deposited production reengineering increase a steel plant’s long-term competitiveness.

Over 30 steel plants in China and overseas have benefited from CISDI’s total consulting solutions, including Baowu Zhanjiang Steel in China and Formosa Ha Tinh Steel in Vietnam.

A screenshot from CISDI’s simulation model for optimising hot metal logistics at Baowu Zhanjiang Steel

✧ Intelligent manufacturing based on CISDigitalTM industrial internet cloud platform

CISDigital is the world of steel’s first industrial internet cloud platform for intelligent manufacturing.

Conventional steel engineering is integrated with 21st century digital expertise - 5G, big data, artificial intelligence, industrial internet and internet of things.

CISDigital’s applications are transforming steel production to super green, creating safer working environments, increasing efficiency and streamlining steel plant management methods.

CISDigital provides a strong basis for life-cycle management of production process data and enables the data to be used to create continual values for a smart steel plant.

CISDigital demo projects:

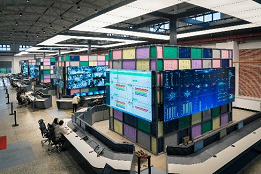

✔ Baowu Shaogang - integrated, intelligent control centre, the first of its kind in the global steel sector

✔ Baowu Zhanjiang Steel - intelligent, autonomous hot metal transport system, the global steel sector’s first artificial intelligence fusion with steel production

✔ Baowu WISCO - centralised operation control and decision centre, the first of its kind in world steel

✔ Baowu Zhanjiang Steel’s centralised water control centre, the first of its kind in world steel

✔ Baowu Bayi Steel - intelligent hot-rolled coil warehousing system, the first of its kind in the world’s steel industry

An island arrangement at Baowu Shaogang’s integrated, intelligent control centre, the first of its kind in world steel

✧ UMCD universal mill

CISDI’s UMCD universal mill tech and equipment features excellent equipment stability, creates greatly improved production efficiency and product precision.

Its first application is in operation at China’s Yongyang Special Steel and is producing light rails. It is the first of its kind for China’s rail sector.

UMCD tech and equipment will also be supplied to Yongyang’s heavy rail production and will result in cost savings of over 50 per cent, a 6-month reduction in construction time and achieve a 60 per cent leaner inventory compared with imported mills.

CISDI’s mill tech offers bright prospects for the steel sections market, which is seeing increasing demands for prefabricated structures, high-rise and large-span buildings.

A UMCD universal mill being assembled at CISDI Equipment Co.