Specialised Topic: Shaogang - CISDI’s new benchmark for intelligent steel manufacturing

Date:2019/3/14 Source: CISDI

Specialised Topic

Shaogang - CISDI’s new benchmark for intelligent steel manufacturing

Link: CISDI’s Intelligent Ironmaking

Committed to

developing intelligent ironmaking products, CISDI has created innovative

solutions for flow, technology and management through big data, internet of

things and artificial intelligence.

The company’s

intelligent products help solve technical issues and production problems,

reduce hot metal costs and improve labour productivity. They create a new model

of integrated ironmaking production.

1) Ironmaking Centralised Control Centre

Core values:

China’s steel

industry has welcomed a new first - the application of an integrated

intelligent control platform and large-scale long-distance centralised control

technology for ironmaking. Created by CISDI, the centre controls blast furnace

ironmaking and its upstream procedures – sintering, coking and stockyard - and

combines the work of dozens of central control rooms.

By re-defining

a steelworks’ organisational structure, the centre fulfills six roles –

integrated control, intensive operation, root safety, standardised logistics,

flow-based manufacturing and flat organisation.

Labour

productivity can be increased by 20 to 40 per cent.

Highlights:

By utilising

internet of things, machine vision and artificial intelligence, the centre can

remotely interlink with site production.

The centre can

also render dynamic assessments on ironmaking production status, intelligently

diagnose critical production problems and make accurate positions and

scientific decisions.

The centralised

control centre for Baosteel Shanghai’s blast furnace

2) Ironmaking Integrated Intelligent Control

Platform

Core values:

In response to

issues caused by lengthy production procedures, the frequent variations of

parameters and the influence of multiple factors, by focusing on flow control

and KPI evaluation the platform keeps track of information (from stockyard to

sintering, stockhouse and hot metal tapping).

The chemical

compositions and lab properties of each batch of raw materials charged into the

blast furnace can be evaluated.

The integrated

ores proportioning model continues the big data analysis of raw materials

batching and preparation, and effect laws on production.

Hot metal costs can be reduced by

$7.5-15 USD per tonne,

a dynamic control for

winning the most competitive hot metal cost. The blast furnace can be kept running

smoothly and stably with an optimised, scientifically proportioned supply of ores.

Highlights:

Intelligent

control of ironmaking production flow

Optimised

logistics and supplies, enabling storage and production to interact

Employs big

data mining technology to

get the most competitive hot metal cost in a dynamic control

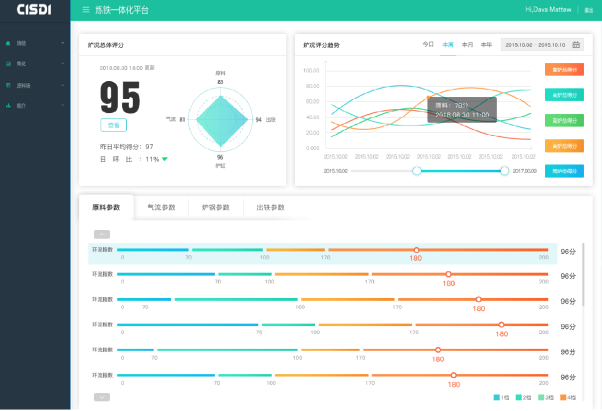

Screen shot of big data analysis for

production

A screenshot of production status diagnosis

3) Intelligent Ironmaking Plant

Core values:

Over 20

mathematical models, developed by using big data and blast furnace simulation,

cover the entire ironmaking and upstream process flows, enhancing ironmaking

production visualisation and digital levels.

As an example,

intelligent ironmaking models in the blast furnace area have made production

smoother. Fluctuations caused by operational misjudgments are now seldom seen.

As a result, the fuel ratio has been reduced by 2 to 10 per cent and 2 to 3 per

cent savings on gas volume have been achieved from using a hot stove combustion

model. Accuracy of forecasting blast furnace heat is now at 89.4 per cent as a

minimum.

Intelligent features:

Blast furnace

ironmaking plant:

●

Hot stove automatic combustion model

●

Heat and hot metal Si content forecast model

●

Operating profile optimisation model

●

Cohesive zone model

●

Intelligent control model for hearth long

service life

●

Molten iron digital control model

●

Distribution optimisation control model

●

Safe hot metal tapping model

Sintering

plant:

●

Excise control system

●

End point control model

Coking plant:

●

Coke oven temperature intelligent control

model

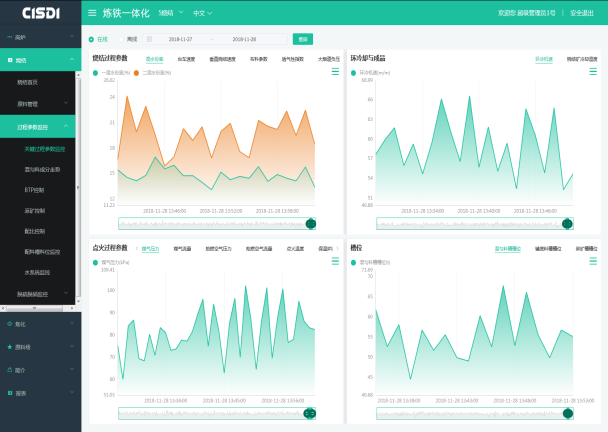

Screen shot of

the blast furnace digital control model

Searching the

optimised profile via a mirror model

Screen shot of

the sintering production monitor

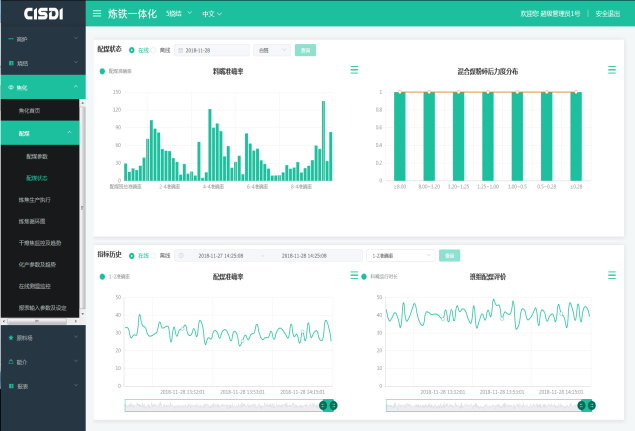

The model for

optimising coal batching at a coking plant

4) Ironmaking Industrial Data Centre

CISDI plans to

create an ironmaking

tech-ecosystem which will be an industrial-level big data center.

To that end, an

industrial big data centre has been created on CISDI’s open and integrated

steel industrial internet platform.

The data for

more than 10 blast furnaces, in China and overseas, has been switched to the

platform.

When the

tech-ecosystem is complete, it will provide steel enterprises with multi-dimensional

benchmarks and information for diagnosis and decision-making.

As it can be seen from the data available

from China, South and South-east Asia and South America, a sharing economy is

now forming.

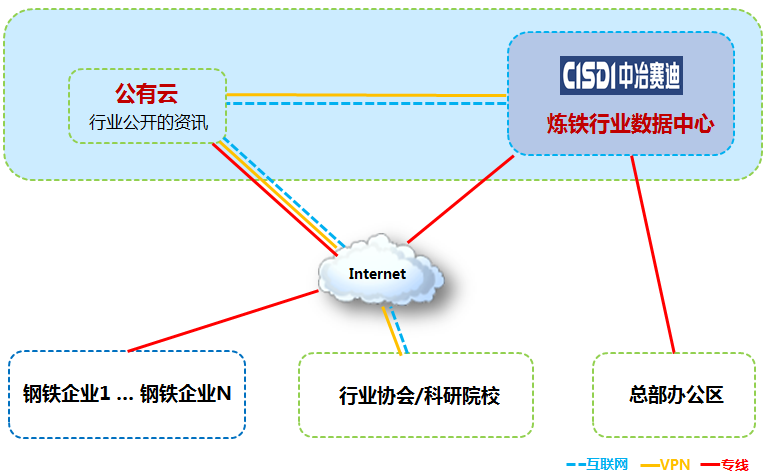

Diagram of an

ironmaking industrial data centre

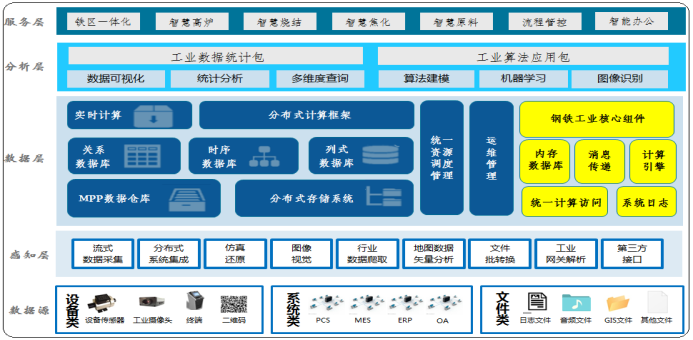

The structure

for CISDI’s steel industrial internet platform